STACK TMS(CEMS) List

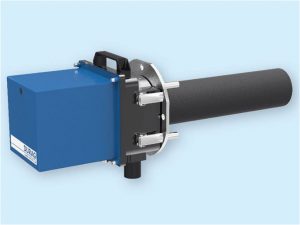

D-R 290 / D-R 290 2nd(NEW)

D-R 220

D-R 320

D-R 800

D-R 808

With its certification range of 0 … 7.5 mg/m3 the D-R 808 is ideally suited for monitoring very low dust concentrations.

F-904-20

ULTRAMAT 23

ULTRAMAT 6

ULTRAMAT 7

OXYMAT 61

OXYMAT 6

FIDMAT 6

CALOMAT 6, 62

SIPROCESS UV600

(e.g. NO, NO2, SO2, H2S)

SIPROCESS GA700

Combine two of the three models – OXYMAT 7, ULTRAMAT 7, and CALOMAT 7 – in a rack or wall-mounted housing. The OXYMAT 7 module is also available with Ex d housing.

LDS 6

The major part of the benefits the in-situ approach is introducing belongs to the simple fact that the measurement is performed non-intrusively and in real-time – without any disturbance or delay due to gas sampling or gas conditioning.

CLD 60 Series

CROSS-STACK UV & FTIR DOAS SYSTEMS

One system can be configured to monitor NO, NO2, SO2, O3, H2S, NH3, CO, CO2, HF, H2O, CH4, Hg, HCl, Cl2, ClO2, CS2, Phenol, Formaldehyde, among other gaseous compounds.

A basic system includes an analyser, an emitter/receiver set, and an optical fiber cable.

The system has been tested and approved by TÜV and MCERTS according to EN 15267, and a range of other international authorities.

LD500 Laser Diode Gas Analyser (CEM)

OPSIS LD500 Analyser is the central unit in the laser diode gas monitoring system.

It can house up to four laser diode heads. Each head is a complete laser control and data sampling system. A built-in PC with LCD display controls the function of the instrument.

The laser diode gas analyser provides very fast monitoring of a range of gaseous compounds. Several gases can be monitored and a multiplexer offers several monitoring paths. Typical compounds are carbon monoxide (CO), carbon dioxide (CO2), hydrogen fluoride (HF), ammonia (NH3), oxygen (O2), hydrogen chloride (HCI), water vapour (H2O), hydrogen disulphide (H2S), methane (CH4), and temperature.

Read about the TDL (Tuneable Diode Laser) Technique >>

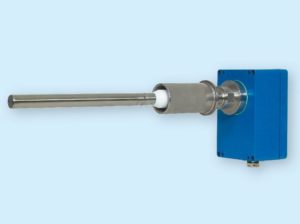

Oxygen Monitor O2000

Measurements are made using the well-established zirconia (zirconium dioxide) sensor principle where a difference of oxygen concentration across a solid electrolyte causes an electric current to flow. The current is detected and amplified, yielding the oxygen concentration. It’s a proven and reliable measurement principle.

The in-situ monitoring means that there is no need for any gas extraction system that could clog or cause other problems during operation. OPSIS O2000 is straight-forward and therefore reliable, requiring a minimum of maintenance.

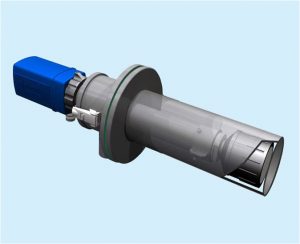

The oxygen monitor consists of a probe inserted in the flue gas, and a control unit. The probe is heated and supplied with ambient air providing a reference oxygen level. A second gas channel leading to the zirconia sensor can be used for quick and precise calibration of the oxygen monitor. The control unit processes the current signal and provides the oxygen concentration to a receiving unit. It also continuously monitor probe performance and initiates regular self-checks. A user interface in the control unit allows for configuration and manually initiated calibrations. Regularly recurring, automatic calibration sequences can also be configured.

A complete OPSIS emissions monitoring system often includes the OPSIS O2000 oxygen monitor combined with OPSIS’ other monitoring equipment such as its UV- and FTIR-DOAS gas analysers and other system components. However, the oxygen monitor can also be used on a stand-alone basis in applications where the oxygen concentration is the only monitoring parameter of interest.

The oxygen monitor has been tested and approved by a number of internationally recognized institutes and authorities, such as German TÜV and British MCERTS. It meets the European directives, and is approved according to EN15267.

The OPSIS O2000 oxygen monitor is the simple answer to your oxygen measurement needs.

Data Logger (DL256)

The data logger hardware is based on modules. It is therefore easy to configure the system to meet a wide range of requirements, and the system can be upgraded by adding modules.

It can be set up to almost any application including data acquisition with status signals, automatic calibration etc. Communication software for remote access via serial link is included.

Together with OPSIS EnviMan modular software system, the data logger forms a complete unit for both data acquisition and data management for industrial applications.

WT256 Web Transfer

The WT256 web transfer collects data from OPSIS analysers and data loggers and pushes the data via FileTransfer Protocol (FTP) or via file copy to a temporary storage site on a TCP/IP based network, such as the Internet.

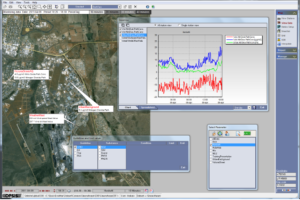

ENVIMAN Software

The MS Windows based EnviMan software offers a range of functions for flexible and cost-effective solutions for industrial applications.

Air Quality Management Modules

- Data acquisition, validation and presentation

- Advanced data presentation and reporting

- Internet presentation

- Emission database

- Real-time dispersion modelling

- Locating emission sources

- Handling of input and output signals

D-FL 100

D-FL 200

JCT GAS PROBE(JES 301 SERIES)

* Emission (CEMS) and process monitoring

* Removal of dust from the sample gas

JCT HEATING PIPE(JER-EH)

* For emission and process monitoring

* For avoidance of acid dew point lower deviaton between sampling point and gas sampling probe

*Combinable with gas sampling probes JES-301 and JES-301L

JCT PORTABLE GAS PROBE(JPES)

* For emission and process monitoring

* For mobile representative gas sampling in dust and humidity containing processes

* For removal of dust from the sample gas stream

* For condensate free transport from the sampling point to the conditioning system or the analyser

JCT COMPRESSOR GAS COOLER(JCL 301)

JCT PELTIER GAS COOLER(JCM SERIES)

* For emission and process monitoring

* For e.g. biogas plants

* Continuous drying of sample gas to a precise low and constant outlet dew point

* Minimises water vapour cross sensitivities and volumetric errors

JCT HEATED SAMPLE LINES(JH3F & JH3FR)

* To stay safely above the acid dew point

* For protection against measured value falsification and frost

JCT PROTABLE PELTIER GAS COOLER(JCP TYPE)

* Continuous drying of sample gas to a precise low and constant outlet dew point

* Minimises water vapour cross sensitivities and volumetric errors